Trusted partner for high-quality wires & cables. Contact Us Today

Single Core Copper Cable

- Home

-

/ Single Core Copper Cable

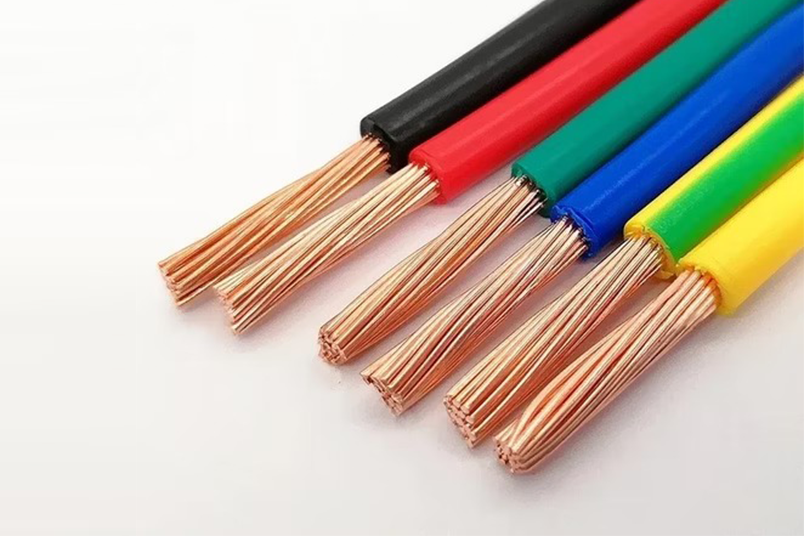

Single Core Copper Cable

PRODUCT DESIGN | |

APPLICABLE STANDARD | IS 694:2010 |

CONDUCTOR | THE CONDUCTORS DRAWN FROM 99.97 % BRIGHT ELECTROLYTIC GRADE COPPER WITH MORE THAN 100% CONDUCTIVITY ARE ANNEALED AND BUNCHED TOGETHER. (CLASS 5) TYPE INSULATION |

TYPE INSULATION TYPES PVC COMPOUND | THE BUNCH CONDUCTORS ARE INSULATED WITH SPECIALLY FORMULATED FLAME RETARDANT PVC COMPOUND WITH A HIGH INSULATION RESISTANCE VALUE. THE INSULATION PROCESS IS CARRIED OUT ON MODERN HIGH SPEED EXTRUSION LINES, WHICH ENSURES HIGH ACCURACY AND CONSISTENCY IN PERFORMANCE |

TYPE C HR COMPOUND | NEONEX CABLES OFFER INSULATION WITH (HR) HEAT RESISTANCE PROPERTIES WHICH SUITABLE TOO BEAR A TEMPERATURE UP TO 85° C. AND ALSO HIGH INSULATION RESISTANCE OF THIS SPECIAL HR COMPOUND. THIS FEATURE NEONEX CABLES ARE CAPABLE TO CARRY HIGHER CURRENT AND BETTER ELECTRICAL AND MECHANICAL PERFORMANCE AT HIGHER TEMPERATURES. HR PROPERTY SUITABLE FOR OPERATION AT HIGH TEMPERATURES. |

COLOUR | RED, YELLOW, BLUE, BLACK, GREEN, GRAY (AND ALSO OTHER COLOUR REQUEST ON CUSTOMER) |

MARKING | THE CABLES ARE PRINTED WITH GENERIC MARKING NEONEX Cables |

APPLICATION | THIS IS A PREMIUM PRODUCT OF ELECTRICAL INDUSTRIAL CABLES FROM " NEONEX CABLES ". THESE CABLES ARE IDEALS FOR WIRING IN CONTROL PANELS, MACHINES AND VARIOUS ELECTRICAL INSTALLATION IN SMALL, MEDIUM AND LARGE INDUSTRIES. |

FEATURE | - MANUFACTURED FROM BRIGHT ANNEALED 99.97 % PURE COPPER CONDUCTORS AND HENCE, OFFER LOW CONDUCTOR RESISTANCE. |

- THESE WIRES ARE INSULATED WITH A SPECIAL GRADE PVC COMPOUND FORMULATED AND MANUFACTURED IN-HOUSE.PVC COMPOUND WITH A HIGH INSULATION RESISTANCE VALUE | |

- EXCELLENT MECHANICAL AND ELECTRICAL PROPERTIES. | |

- PROGRESSIVE SEQUENTIAL LENGTH MARKING ON VERY METER. | |

ISO CERTIFICATION | ISO 9001:2015, IS0 45001:2018, IS0 14001:2015, CE, RoHS |

PRODUCT CERTIFICATION | IS 694:2010 7098 P-1 TUV RHEINLAND CERTIFICATE No. R 60160877 |

TECHNICAL DATA | |||||

NO MINAL CROSS SECTIONAL AREA | NUMBER/ NOMINAL DIA OF WIRES (MAX) | THICKNESs OF INSULATION (NOMINAL) | APPROX OVERALL DIA | MAXIMUM DC RESISTANCE OF CONDUCTOR AT 20° C | MAX. CURRENT CARRYING CAPACITY |

MM2 | NUMBER/ MM | MM | MM | Ω/KM | Amps |

1C X 10 | 140/0.3 | 1.0 | 6.20 | 1.91 | 40 |

1C X 16 | 224/0.3 | 1.0 | 7.80 | 1.21 | 55 |

1C X 25 | 354/0.3 | 1.2 | 9.80 | 0. 780 | 70 |

1C X 35 | 495/0.3 | 1.2 | 10.80 | 0.554 | 90 |

1C X 50 | 703/0.3 | 1.4 | 12.80 | 0.386 | 120 |

1C X 70 | 988/0.3 | 1.4 | 15.00 | 0.272 | 190 |

1C X 95 | 1349/0.3 | 1.6 | 17.50 | 0.206 | 250 |

1C X 120 | 608/0.5 | 1.6 | 19.00 | 0.161 | 290 |

1C X 150 | 760/0.5 | 1.8 | 20.80 | 0.129 | 340 |

1C X 185 | 931/0.5 | 2.0 | 24.00 | 0.106 | 380 |

1C X 240 | 1216/0.5 | 2.2 | 27.00 | O.0801 | 460 |

NOTE:

- THE NUMBER OF WIRES AND DIAMETER MENTIONED IN THE TABLE ARE APPROXIMATE AND NOMINAL, HOWEVER THEY SHALL MEET THE REQUIREMENTS OF CONDUCTOR RESISTANCE AS PER STANDARDS. IS 8130

- TOLERANCE: ABOVE 10 SQ MM +/-1.2 MM

- THE ABOVE DATA IS INDICATIVE AND MAY BE REVISED WITHOUT PRIOR INFORMATION. NEONEX CABLES WILL NOT BE LIABLE FOR ANY DAMAGES ARISING OUT OF INCORRECT APPLICATION.

×

×